Prepare your inlay first, then add it to the headstock overlay prior to gluing it the the neck.

Glue your inlay to the surface with a bit of CA, cut around it to create the opening, flip the overlay over and clamp the inlay (with still-attached overlay shape) into a black epoxy-filled cavity, sand the excess height on the backside smooth when the epoxy is set.

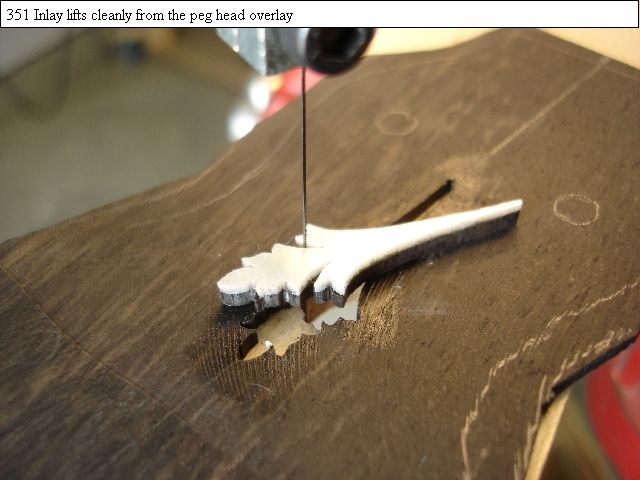

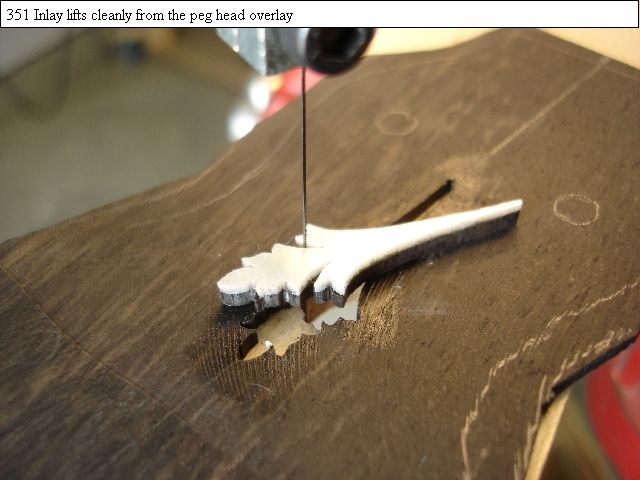

It's quite easy to do quick and perfect inlays this way. If you're making multiple instruments you should be getting your logos already pre-cut from one of the custom work pearl supply houses, so it becomes very cost-effective to do it that way. Here's a shot of a pre-cut inlay going into a banjo peg head overlay.