Page 1 of 1

Resawing With Hand Tools.

Posted: Fri Jan 20, 2017 12:19 am

by Gilbert Fredrickson

I can get three 3/16" guitar back panels out of a 15/16 board, right? I have some stock for parlor guitars that will have three piece backs. The boards are 4 1/2" x15/16ths" in the proper lengths. Saw kerf is .027 universal cut hardwood Kataba. Thanks. It should work.

Re: Resawing With Hand Tools.

Posted: Fri Jan 20, 2017 12:01 pm

by Bryan Bear

That is a question only you can answer based on your skill and experience with that saw and set-up. I know that I cold not, but that is not saying a whole lot <g>

Re: Resawing With Hand Tools.

Posted: Fri Jan 20, 2017 12:56 pm

by Rodger Knox

That would be 2 cuts, with 3/16" for each cut's kerf and cleanup. A 0.027" kerf sounds pretty thin for a handsaw stiff enough to resaw 4 1/2" thick, and 3/16" is pretty thick for a back, so you do have a little more room for error. It would be easy with a bandsaw, I've gotten four 1/8"thick slices from a 3/4" thick board.

You would probably want to use a rip saw, and it would be a lot of work, but I believe it possible. As Bryan said, it depends on your skill with the saw. I THINK I could do it.

Re: Resawing With Hand Tools.

Posted: Fri Jan 20, 2017 1:10 pm

by Brian Evans

The traditional hand tool for resawing is a bow saw or a frame saw. I tried it once, in a wider softer board, and it wandered badly. You want at total of 9/16" of wood out of15/16 rough, so if the wood is fairly true that gives you 6/16" of kerf, which is lots of room to play with. I would do that with two passes on a plain old table saw, a 10" tablesaw can do that easily and you'd be finished almost before you started. If I was really going to do it with a hand saw I would pass on the thin blade saw and use a freshly sharpened and set Disston D-8 type rip saw, coarse tooth, lightly set. Coarse tooth clears the sawdust well, and lightly set means the kerf is not too aggressive and the wide blade tends to take a straighter path with a slightly tight kerf. My grandfather would have done that job without even thinking about it, and to be honest the saw I would use is his saw anyway...

http://www.vintagesaws.com/catalog/inde ... &cPath=1_4

Re: Resawing With Hand Tools.

Posted: Fri Jan 20, 2017 2:08 pm

by Beate Ritzert

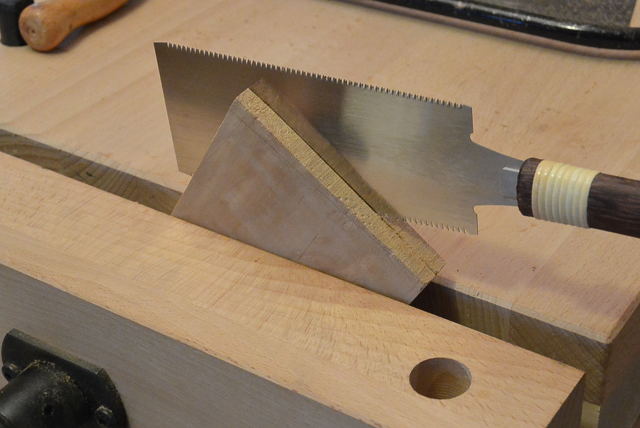

I would rather do it with a Japanese saw (cut on pull) and not with a European one (cut on push). On a smaller scale i did it that way (that wood is pear, hard but easy to work on). Please notice that i was using the side of the Ryoba dedicated to cut along the grain. I also tried the cross grain side, but it was slower and to my surprise the cut was rougher.

BTW: blade width 0.014 in.

A while ago i did a cut in a swamp ash body with a (cheap) universal cut kataba. That was *no* fun. From this experience i would really suggest to use a dedicated saw, and if You are good in using japanese saws (in contrast to me) i would use a more expensive professional quality tool - which is more delicate to handle than the mass production saws.

BTW: some frame saws (large European ones) can be equipped with "japanese" blades to cut on pull. I can imagine that something like this would be a good tool for such a purpose.

Re: Resawing With Hand Tools.

Posted: Fri Jan 20, 2017 3:32 pm

by Gilbert Fredrickson

Thanks so much for your help. A traditional rip saw and a kerfing plane are recommended by those who use only hand tools for resawing. A bow saw is suggested but it is difficult for many to use. The suggestions you've all made will really help. I will start a kerf down the boards then cut them with the Ryoba I have at hand. Thanks again.

Re: Resawing With Hand Tools.

Posted: Fri Jan 20, 2017 3:46 pm

by Gilbert Fredrickson

Four 1/8" cuts from a 3/4" board is amazing. Legends are founded on skills like that!

Re: Resawing With Hand Tools.

Posted: Fri Jan 20, 2017 11:51 pm

by Bryan Bear

Don't forget to let us know how it comes out.

Re: Resawing With Hand Tools.

Posted: Mon Jan 23, 2017 3:02 pm

by Rodger Knox

Gilbert Fredrickson wrote:Four 1/8" cuts from a 3/4" board is amazing. Legends are founded on skills like that!

It's not that amazing, that's 3 cuts at 0.083" each. The saw kerf is 0.025", that leaves 0.058" per cut for error. The board I cut was only 5 1/2" deep (a 1x6 maple from HD), so that was plenty of room. A 10" wide board would be more difficult.

Re: Resawing With Hand Tools.

Posted: Wed Jan 25, 2017 1:44 am

by Mark Fogleman

If you haven't used a kerfing plane it will make hand resawing much easier and precise. Use it to create a deep kerf around the perimeter of the board you are resawing. This creates the least difficult path for your saw instead of letting your saw choose it's own drift. The standard saw plate that Tom Fidgen recommends in his book

https://theunpluggedwoodshop.myshopify. ... dshop-book is too thick. Get a replacement blade for your saw or a ripping blade that matches the spec you need. Jim Hendricks has an excellent write up on how he built his here:

http://contrib2.wkfinetools.com/hendric ... ane-01.asp

Re: Resawing With Hand Tools.

Posted: Wed Jan 25, 2017 12:26 pm

by Todd Stock

My frame saws for solo resawing all had pull blade orientation...a slightly touched up 3 tpi x 1/2" band saw blade worked just fine for resaw, but having two people makes it a lot easier to stay on track.

Re: Resawing With Hand Tools.

Posted: Wed Feb 08, 2017 8:46 am

by Beate Ritzert

Quite recently i read a contribution somewhere else where the author ran into problems during resawing. He cut a top for s solid body into two thin slices. 18 cm width with a normal and relatively short Japanese saw. In the centre of the plate the saw blocked because the cut became round while the outer trace of the cut remained straight.

Mhmm, i would like to understand how happened and even more how to avoid it.

Re: Resawing With Hand Tools.

Posted: Wed Feb 08, 2017 10:22 am

by Bob Gramann

When a bandsaw cuts a curve along the length of the blade, it's usually because the saw is dull.

Re: Resawing With Hand Tools.

Posted: Wed Feb 08, 2017 12:16 pm

by Mark Fogleman

Beate Ritzert wrote:Quite recently i read a contribution somewhere else where the author ran into problems during resawing. He cut a top for s solid body into two thin slices. 18 cm width with a normal and relatively short Japanese saw. In the centre of the plate the saw blocked because the cut became round while the outer trace of the cut remained straight.

Mhmm, i would like to understand how happened and even more how to avoid it.

It's likely the sawyer was trying to cut on the pull

and push stroke. Japanese type saws are designed to cut on the pull stroke when the saw plate is under tension and the sharp edges of the teeth are facing the direction of motion. When putting downward pressure on the push stroke the blade can warp. This can cause the saw to create its own path and cup. To avoid this, lighten the downward pressure on the saw when pushing forward, allow the teeth to do the work on the pull stroke. Also as I posted above, a kerf plane makes resawing much easier and precise with a handsaw.

Re: Resawing With Hand Tools.

Posted: Wed Feb 08, 2017 12:47 pm

by Barry Daniels

The set of the middle of the saw could be off which would make that part of the cut slanted.

I have an old Diston handsaw that belonged to my Grand Father but the saw is warped and it always tracks to one side.