Page 1 of 2

Best practice dovetail neck joint

Posted: Mon Apr 03, 2017 12:30 pm

by Brian Evans

I have to date done bolt on necks, and I'm reasonably pleased with that. My feeling is the downfall of such a bolted joint is the inevitable crushing of the wood under the bolt head over time, even with a belleville washer to aid in maintaining tension. So in the interests of science and my personal growth, I feel like learning how to make a dovetail joint. I plan to build router jigs to do this, and make a bunch of test tries before I attack a guitar body. I have two questions that I would appreciate help with...

What jig? I have the layout of the Benedetto jigs, which route the neck dovetail tenon and set the neck cheek angle at the same time, and that looks fine, and the corresponding jig to cut the body mortise, but have there been advances in the art over the past 20 years?

What shape tenon? The traditional triangular joint mirrors the tapered aspect of older style neck heels, and one imagines draws the joint pretty tight as it is pressed into final place, with the relatively steep angle. At the same time, getting it a tad wrong or having some differential shrinkage in the neck tenon would force it to loosen up more. The Benedetto design is a nearly square tenon and mortise, he puts in 1/16" of taper over the length of the joint to make it close up tight as the neck is fitted. One imagines a fully square joint with no taper, a classic dovetail simply tightly fitted. Seems harder to make, and I can't think of an advantage. Again, what is the current state of the art in this?

Thanks in advance for indulging me.

Brian

Re: Best practice dovetail neck joint

Posted: Mon Apr 03, 2017 7:32 pm

by Beate Ritzert

One imagines a fully square joint with no taper, a classic dovetail simply tightly fitted. Seems harder to make, and I can't think of an advantage.

I did such a joint in my 1st problem child guitar, the thinline archopt i just made playable. I found it extremly laborious to achieve a neck line parallel to the middle axis of the guitar while fitting the glueing surfaces tightly (i was working with hand tools). Same trouble, of course during the recent neck reset. Therefore i would recommend a V-shaped joint.

Apparently, a dovetail joint is not absolutely necessary. An easier alternative might be a joint similar to the neck joint of a violin - more or less pronounced V shape, no dovetail. If the surface fit is tight and the glueing surfaces are large enough, this joint is stable. A pretty well known instrument with such a neck joint is the Höfner 500/1 bass (the Beatles bass). But probabla many of the German archtops from the late 50s/early 60s have it.

May i remark that such a joint work well only if done with HHG or fish glue; PVA glue cannot be used due to its creeping property. Even better qualities.

Re: Best practice dovetail neck joint

Posted: Tue Apr 04, 2017 11:02 am

by Barry Daniels

If your only issue with bolt on necks is wood crushing under the bolt head, that can be solved by several approaches:

1) bigger washer

2) flanged bolt head

3) a layer of crush resistant wood (ebony or rosewood) laminated to the head block

4) a piece of brass or steel with holes for the bolts

4) there are probably other ways I haven't thought of

There might be other reasons to try a dovetail, but I don't think the limitations of bolt-on techniques should be one of them.

Re: Best practice dovetail neck joint

Posted: Tue Apr 04, 2017 11:36 am

by Brian Evans

The reason I want to do a dovetail joint is personal growth. Limitations of bolt on joints have nothing to do with it. I'm also about to do a Howe-Orme joint, as soon as I find a source for capstan bolts...

Re: Best practice dovetail neck joint

Posted: Tue Apr 04, 2017 6:08 pm

by Barry Daniels

That is reasonable. Doing a dovetail is a good experience and some clients may demand one for a custom guitar. I did my first dovetail on my first archtop using Benedetto's method. It turned out well but I did use a jig with a router.

Re: Best practice dovetail neck joint

Posted: Tue Apr 04, 2017 7:07 pm

by Mike Conner

Brian,

The details of my dovetail joint method are in my Journal. The jigs were pretty easy to make, and I made quite a few dummy necks and joints until I was happy with the fit. For convenience I use a standard 3/4" dovetail router bit and guide collar, and designed the length of the tenon, etc from the bit dimensions. (I have reasonable hand tool skills and do the final fitting by hand, but I'm not confident enough to make the dovetail entirely by hand).

I don't use glue and lock the neck in using a long screw through a strap button.

Don't forget to allow for the tenon length when laying out the neck blank. The 3/4" router bit makes a 3/4" long tenon.

Go for it! Make some test necks and see if it works for you.

//mike

Re: Best practice dovetail neck joint

Posted: Tue Apr 04, 2017 10:21 pm

by Alan Carruth

Beate wrote:

"An easier alternative might be a joint similar to the neck joint of a violin - more or less pronounced V shape, no dovetail. "

I've been using such a single taper mortise for years. I started out with a glued straight M&T, but it was pointed out that that this sort of joint is very hard to get apart. When you steam it the wood swells and locks. I went to the single taper after that; sides parallel in the plan (top) view, and tapered toward the heel. THis has worked well, but you do have to fit it very carefully. In particullar, you must do something to lock in the lower surface. On a violin neck it's the contact of the heel with the end button of the back that actually hoolds the neck in; if the button breaks off the neck folds up. On my guitars I don't carry the tenon all the way down to the back. Instead I make the bottom surface about 5/8" (15mm) wide. The bottom of the mortise is under cut, so that the tenon is slightly longer on the free end than it is at the base where it coomes off the neck heel. This bottom surface must be well fitted and glued, or the neck will fold up eventually. This has happened to a couple of my students.

I've recently switched to using bolt-ons. It's like Chrchilll said about democracy; it might not be great in thory, but compared with all the others it's the best in practice.

Re: Best practice dovetail neck joint

Posted: Wed Apr 05, 2017 2:10 am

by Randolph Rhett

Alan Carruth wrote:Beate wrote:

I've recently switched to using bolt-ons. It's like Chrchilll said about democracy; it might not be great in thory, but compared with all the others it's the best in practice.

On your archtops? Do you use a butt joint or with a straight/v tenon? Inserts or lag screws? Since you brought it up...

Re: Best practice dovetail neck joint

Posted: Wed Apr 05, 2017 3:48 am

by Arnt Rian

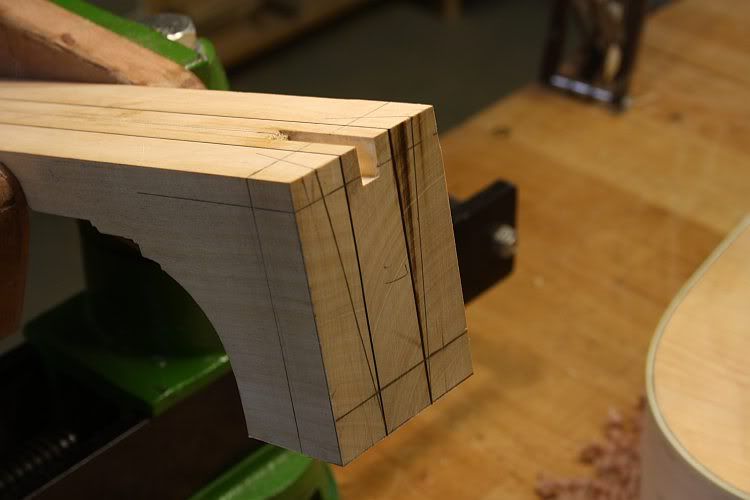

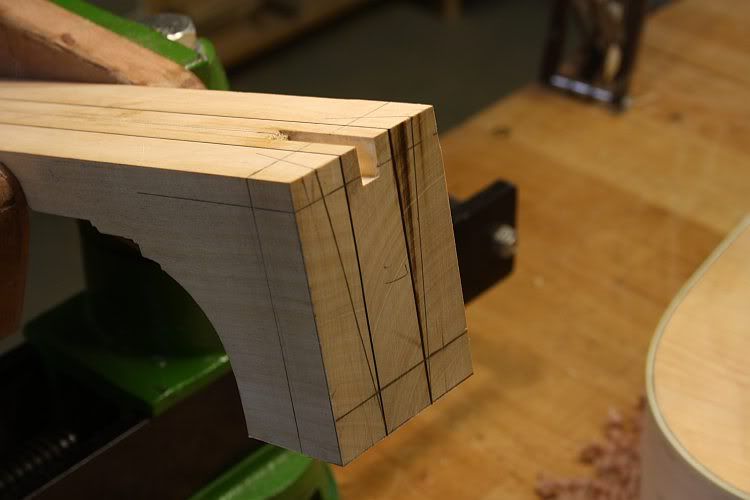

They are not that hard to do by hand, actually. Just study the geometry, so you have a clear idea of how everything is going to line up, and be precise when marking and cutting. Here are some pictures of a tapered dovetail I did few years back.

Marking

Cutting

Done

Cutting the mortise in the body

Using the center line finder to make sure the neck lines up, as I'm trimming the joint

Using chalk to check the fit

Finally, the neck can be glued to the body.

[/quote]

Re: Best practice dovetail neck joint

Posted: Wed Apr 05, 2017 5:48 am

by Beate Ritzert

Side questions:

shaping the neck after glueing it to the body?

Always a separate neck extension? Why? Just because that makes it easier to cut the dovetail?

Re: Best practice dovetail neck joint

Posted: Wed Apr 05, 2017 6:26 am

by Arnt Rian

Hi Beate, not sure if you are asking me, but I prefer to shape the neck after joining it to the body, as it's hard to do without fingerboard and neck extension in place. The separate neck extension is for convenience; one less surface to fit while tinkering with the neck joint. It could be attached prior to gluing the neck I suppose, IIRC that'w how Benedetto shows it in his book, but I see no real benefit. Either way, it should not affect the cutting of the dovetail, which is a separate operation. I should add that I have adapted this technique from mandolin building, its might not be that common for guitars.

Re: Best practice dovetail neck joint

Posted: Wed Apr 05, 2017 6:30 am

by Beate Ritzert

Randolph Rhett wrote:

On your archtops? Do you use a butt joint or with a straight/v tenon? Inserts or lag screws?

Allan Carruth wrote:I went to the single taper after that; sides parallel in the plan (top) view, and tapered toward the heel. THis has worked well, but you do have to fit it very carefully. In particullar, you must do something to lock in the lower surface.

No, i did not use it, i just saw it during repairs.

Here a view on the end block of the guitar i am currently trying to repair. That does not look as if there was any dovetail, doesn't it? BTW: that heel is broken, roughly at half height, and the neck has started to fold on. (And please, if You like to discuss on the repair of that heel here:

http://www.mimf.com/phpbb/viewtopic.php?p=48919#p48919}.

Re: Best practice dovetail neck joint

Posted: Wed Apr 05, 2017 6:57 am

by Beate Ritzert

Arnt Rian wrote: It could be attached prior to gluing the neck I suppose, IIRC that'w how Benedetto shows it in his book, ...

Thats why i asked. And all the examples i saw - my first and only archtop and the two repairs - all use necks with fully integrated neck extension, and i found it really difficult to cut the dovetails.

I just looked up the reference book i used during my old build - the Jahnel ("Die Gitarre und ihr Bau"). He describes a neck joint from the violin family, including the extension of the bottom plate to hold the neck. Potentially strengthened with a screw. I did not trust that connection, and i had only PVA glue at hand and therefore used dovetails because these will inherently block folding of the neck.

Re: Best practice dovetail neck joint

Posted: Wed Apr 05, 2017 7:29 am

by Brian Evans

So interesting to see and hear the different ideas and methods. I appreciate it very much. I have done hand cut dovetails on drawers and such, although not on a guitar neck, so I'm familiar with that technique, believe it or not my goal for this expedition is to learn how to make and use router jigs. I have a great fear of routers and I want to conquer that. I have read that several well regarded builders use no glue on their dovetailed necks and secure them with a screw, so hearing about that again was great. A big lightbulb went on when I read of Alan's straight-sided tapered mortise with the extension at the toe, and the violin neck glued to the back button. Putting the physical lock exactly where needed.

Brian

Re: Best practice dovetail neck joint

Posted: Thu Apr 06, 2017 2:53 pm

by Alan Carruth

I used to use the straight up violin style joint on archtops, until one came back from a show broken. It had quite clearly been abused by the carrier (UPS), but, of course, they said it was 'improperly packed' (obviously, since it broke, right?), and refuse to pay up even though it was insured. At any rate, the package was dropped tail side down, and the neck folded up, breaking the back in the process. The only good repair would have been to replace the back. In the end, I put it back together with a big screw and sold it to a student when I moved to a new shop.

On violins that sort of break goes along the purfling line across the lower end of the button. It's possible to 'half edge' the back, regluing the button onto the repair, and touch up the edge so that its not obvious. On a guitar it would be even better in some ways, since you'd cover the edge with the binding. Unfortunately, I didn't carry the purfling rout across the heel, so it was a jagged break.

Re: Best practice dovetail neck joint

Posted: Thu Apr 06, 2017 8:51 pm

by Alan Carruth

Here's a picture of the neck joint I use these days. This one is a student's guitar that just got it's last coat of varnish yesterday. It's his first instrument, BTW, although he is a good woodworker.

Re: Best practice dovetail neck joint

Posted: Fri Apr 07, 2017 4:45 am

by Beate Ritzert

Thanks for sharing this. In other words: it is remarkable, that the joint i showed has not folded up despite its lack of a fixing surface, and i am well advised to add one - by, for example filling the gap between the foot of the heel and the bottom plate?

Re: Best practice dovetail neck joint

Posted: Fri Apr 07, 2017 1:33 pm

by Alan Carruth

I would do something to see that the bottom surface is glued down. I've only had this type of joint fail a couple of times out of something like a hundred and fifty instruments; both on guitars made by my students. Both had clearly not been in contact at the bottom when we opened them up. It's a reasonably strong joint, and might well hold without that. OTOH, since there's more leverage on an archtop, due to the higher over stand and shallower body, caution is due.

Re: Best practice dovetail neck joint

Posted: Fri Apr 07, 2017 2:26 pm

by Randolph Rhett

Thanks Alan! I see a hole in the mortise, but nothing on the tenon. How does that go together? Will your student add a lag screw into the neck?

Re: Best practice dovetail neck joint

Posted: Fri Apr 07, 2017 10:24 pm

by Alan Carruth

The hole was for a screw to attach a handle to hold onto when varnishing the box. With a flat top you can hold it by the sound hole, but that doesn't work on arch tops.

[/quote]

[/quote]